The annual TPCA Show and IMPACT Conference were held from October 22 to 24 at Taipei Nangang Exhibition Hall Hall 1. MKS' two strategic brands, Atotech and ESI, impressed show visitors. Whether it was the crowded booth, the numerous paper presentations at the IMPACT conference, or the specially held "Enabling AI and HPC: Technology Inflections Across Advanced Packaging and Interconnect" forum, leading companies in the PCB, IC substrate and semiconductor industries attracted much attention.

In 2025, MKS will not only participate in the exhibition again, but also many senior leaders from MKS headquarters, including CEO Dr. Li, will also gather together from all over the world. In addition to the exhibition, the MKS team also had in-depth exchanges with important customers, including the Taiwan Circuit Board Association, and exchanged valuable opinions with each other to make the cooperation between MKS and customers closer. During this period, the CEO also accepted interviews with international media, allowing the industry to better understand MKS and its contributions and efforts to the industry.

Teams from both MKS strategic brands came together to showcase the newly combined company’s combined expertise in advanced PCB drilling systems, lasers, optics and braking systems. MKS also has the process chemistry and equipment to support current process and yield optimization, as well as next-generation product development, such as for advanced material processing, through-hole forming, glass packaging carriers, solar, batteries, etc. One of the highlights of the show is Optimize the Interconnect℠, which can be demonstrated through MKS Atotech and ESI products and services. MKS provides optimized interconnect concepts and provides printed circuit board (PCB) and advanced electronic packaging customers with a wide range of products and services for creating interconnects for state-of-the-art PCB and IC packaging designs. Services include PCB and advanced electronic package interconnect creation and evaluation services, access to MKS Technology Centers for installation, setup and troubleshooting services, application development services, application labs and support, design and development services, and maintenance, repair and calibration services.

This unique combination of MKS’ expertise in through-hole drilling and routing, as well as electroless plating, provides customers with the opportunity to accelerate their product roadmaps, solving challenges associated with new materials and finer feature sizes, resulting in faster time to market through higher quality output and more efficient interconnect creation.

▲ MKS exhibited physical samples (treated glass substrates) for the first time at TPCA

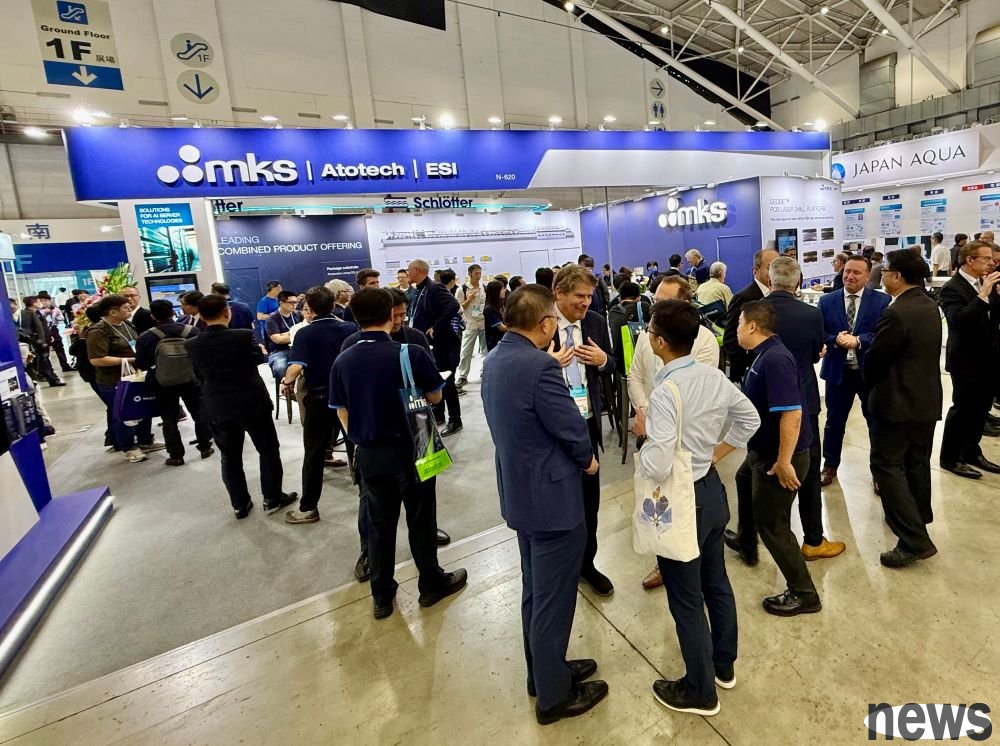

▲ MKS’ booth was crowded with visiting customers and experts

MKS offers a broad range of technologies and capabilities such as laser, precision optics, motion control, beam metrology, through-hole drilling systems and process chemistry to provide unique solutions to optimize the manufacturing of PCB and advanced electronic packaging interconnects, a critical part of the overall PCB and advanced electronic packaging manufacturing process. At this exhibition, MKS also exhibited a physical sample for the first time, a 510 cm X 515 cm treated glass substrate. This sample uses four related processes from Ato Technology's three product groups throughout the entire manufacturing process, including VitroCoat® GI, Cupratech® GIM, Conformal Plating, and EcoFlash® processes. If you want to know more relevant information, please contact the Ato Technology team.

Global Marketing Director Daniel Schmidt said: "We understand the importance of providing our customers with the best solutions and services, including sustainable products and energy-saving equipment, to create a win-win situation for our customers." Throughout the week, local and international leaders from all over the world met with teams, customers, partners and potential customers to exchange views on the future, paying special attention to the latest industry trends and challenges. Teams also made special efforts to warmly welcome and introduce the latest technologies and solutions to key industry players and customers. The team demonstrated MKS's new synergies and total solutions to Taiwan's PCB industry, including PCB production equipment (wet-on-wet process equipment, laser systems and auxiliary equipment), chemistry, software and services. In the two years since the acquisition of Ato Technologies, the industry, especially MKS’s customers, have shown a high degree of confidence in the company’s integration and believe that these solutions will contribute to future planning of its product and manufacturing roadmap.

▲ MKS’s industrial forum was packed

▲ MKS Industrial Forum has a strong lineup of lecturers

In the IMPACT technical conference, the MKS team published 8 papers. Among them, the "IMPACT Industrial Forum" held on October 22 from 13:00 to 15:00 pm is one of the focus activities of this event. Industry leaders in specific fields are invited to talk about their contributions to the development and manufacturing of artificial intelligence. The discussion on glass substrate technology has benefited the participants a lot. This year, we tried to use panel discussion for the first time, allowing the audience to have a more comprehensive exchange with the lecturers.. Daniel Schmidt, Global Marketing Director, said: "We are honored to partner with IMPACT again to host this forum. The special industry conference helped our company attract attention to industry trends, challenges and possible solutions. Many issues were raised and discussed during the conference, which shows that we have contributed not only in terms of solutions, but also in terms of technological development within our industry."

Finally, this year Ato Technology and ESI not only sponsored and participated in the well-known IMPACT conference, but also joined the newly upgraded open seminar "TPCA Show 2025 Technology Solution Trend Conference" series and delivered two special speeches. The Taiwan STT team presented "Exploration of line formation technology in advanced packaging", and the equipment team presented "A closed-loop IIoT platform for smart, lean and sustainable PCB manufacturing", which brought profound inspiration to the industry and attracted enthusiastic participation from many professional audiences.